When to use 2D or 3D Data for recognition

When to use 2D or 3D Data for recognition

Ing. Buero Dieter Munkes News • June 2, 2016

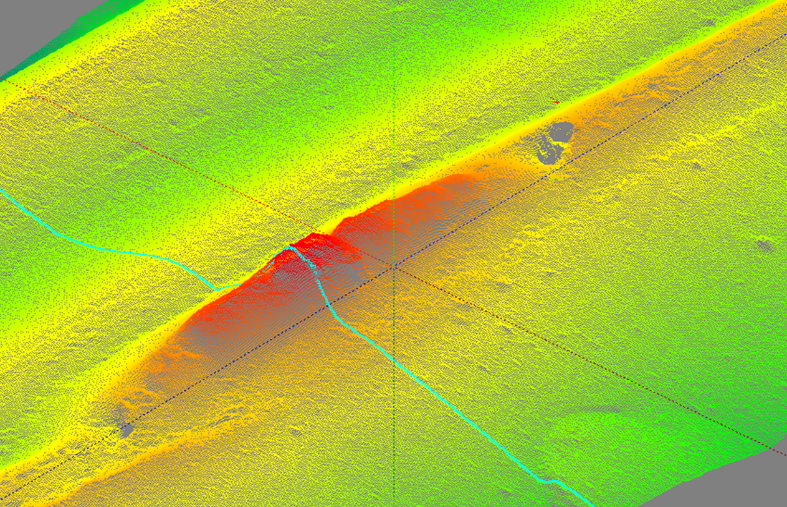

3D scan, laser welding

2 optical technologies are actualy used for inspection or recognition. There is photo camera and the 3D measurement in different ways.

First a few words about photo camera.

Today I use TPC/IP camera for easy connectivity. USB3 would be ok to.On market you get fooded by cheap cameras.

Let´s compare a little.

What are the differences:

The industrial Version have:

- Bigger lenses = more light , less deeps of focus!

- Bigger amount of possible lenses

- Flash trigger output

- very short exposure times (32usek)

- Global shutter

- Monochrome Sensors to avoid Bayer interpolation.

The cheap ones have:

- very small sensors and lenses = less light but deeps fokus is fine

- mostly fixed lens

- no flash

- rolling shutter and with this unusable on moving objects.

- normaly color sensor

Extracting the details from the picture you needed for your propose depends on ilumination.

This is the key to success. You can not compensate any wrong lightning by software.

Mostly I need to switch different lights in different positions to get a picture for every parameter i want to extract.

(You use both eyes and/or move your head to do the same)

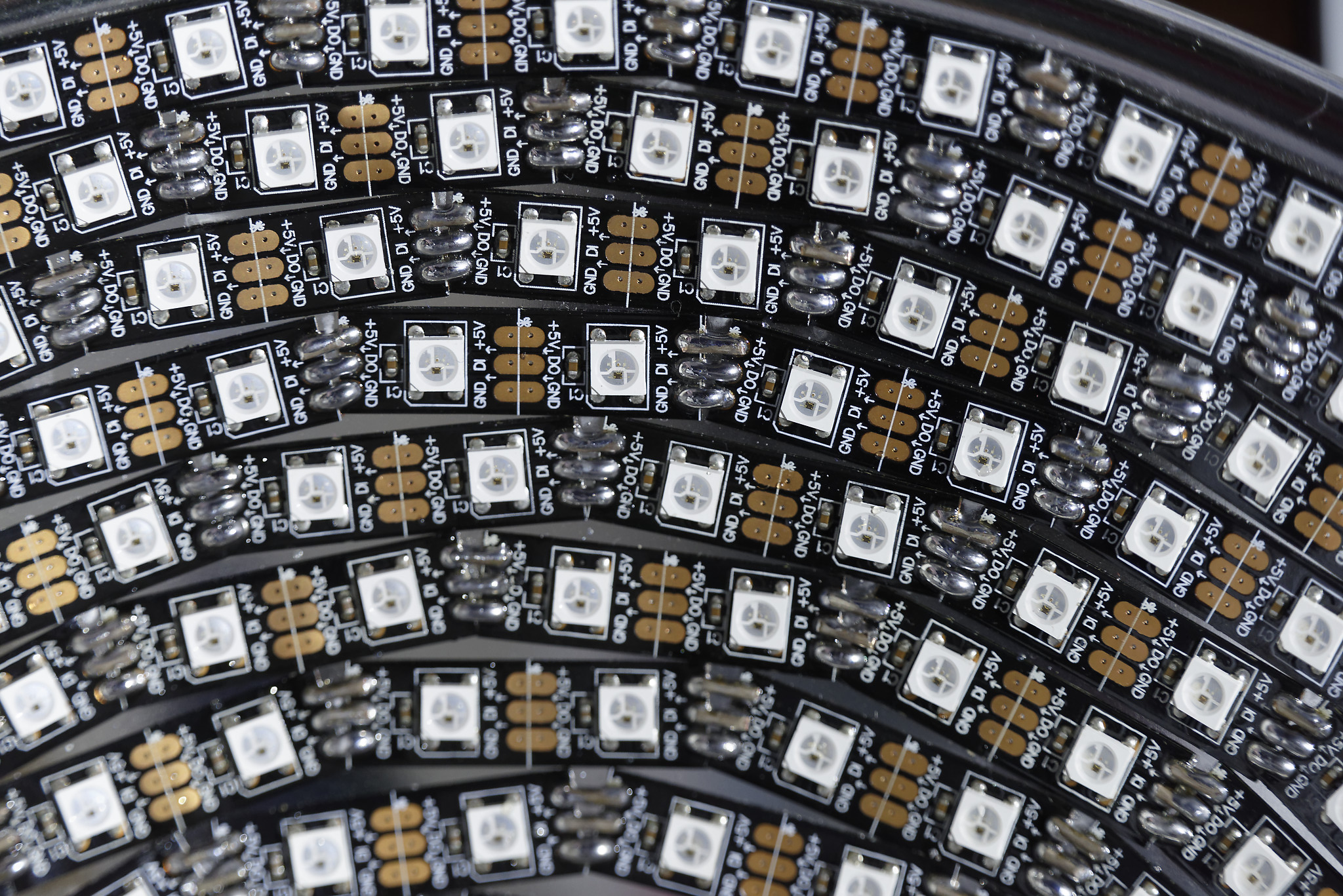

Let´s go to 3D

I worked with different kind of sensors:

- Time of flight of a scanned Laser (slow)

- Time of flight camera like sensor (low resolution)

- Reflected Laserline under constant angle. (medium fast)

- projected pattern (never tried this)

- Dual camera like our eyes (never tried this )

All of this methodes have different ranges and accuacy.

But common is they are all more expensive than an photo camera.

From view of software, in 3D data it is more easy when to find edges , objects.

There is no foreign light no reflections. (Laser systems)

But, no colors, nothing like photo flash.

Now my selection of method.

2D camera

- low budget

- low requirement

- fast

- recognition not measure

3D sensor

- control robotics handle 3d results

- measure deeps or size or distance

You can measure with 2D camera too but mostly need telecentric components. This easily explode your budget.

Sometimes i need both when it comes to measure and color.