Prototyping

just testing….

Ing. Buero Dieter Munkes News • June 2, 2016

Neue Ansätze ausprobieren erfordert das man mal schnell etwas aufbaut.

Die ganze Story.

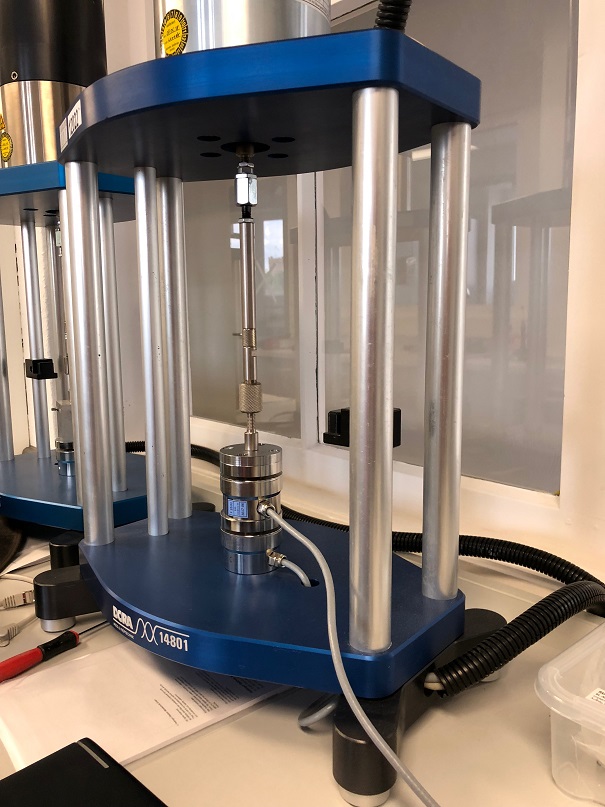

In 2010 wurde eine Prüfmaschine für eine EN14801 (Lebendauer Zahnimplantate ) entwickelt.

Damals mit automatisierungs Komponenten von Beckhoff, eigenem Leistungsteil und Vorverstärkern.

Im Verbund mit 8 Prüfstationen kann eine SPS das leicht handhaben. Mit weniger Stationen wird der Kostenanteil der Steuerung überproportional groß.

Die Lösung bestand aus Beckhoff IO, SPS , einem PC Win7 sowie einer Betriebsoftware geschrieben unter Delphi.

Folgende Nachteile: Einen PC mit allem Security updates.. die Enduser installieren zusätzliches, binden diesen ins Unternehmesnetzwerk ein.

Dies mag bequem sein, wird aber gerne zum Pflegefall.

Ziel 1-2 Stationen?

SPS -> zu teuer für Serie.

PC -> zu teuer bez. Wartung und pflege.

Messtechnik könnte Rauschärmer sein->Neubau

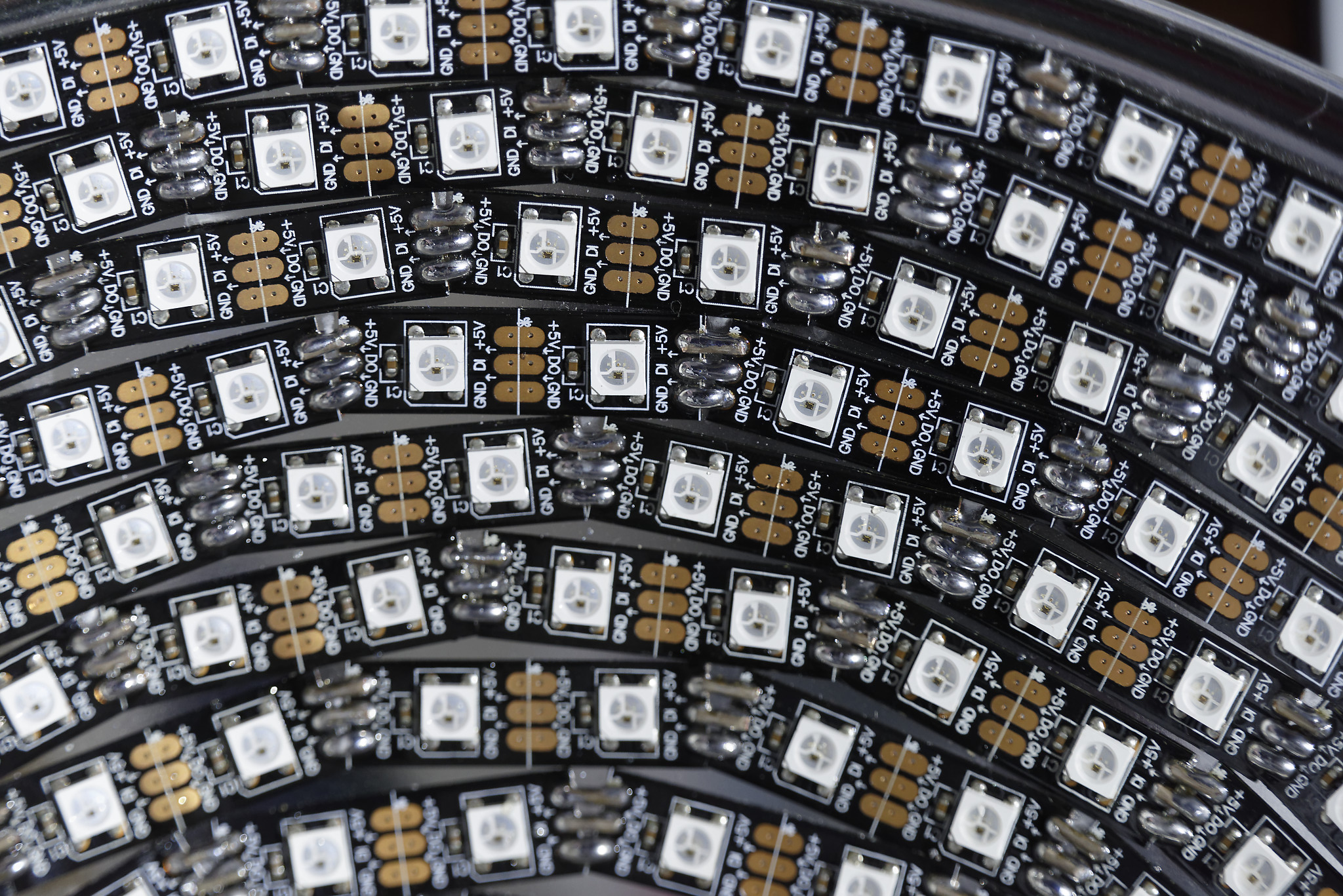

Da wäre als neuer Ansatz die SPS auf einen Microcontroller zu verlagern. Den PC gegen einen Raspberry zu tauschen. Die Benutzeroberfäche mit allen Grafiken in HTML5.

Fazit-> Wirklich alles neu machen.

Zur Abschätzung der Risiken wurden ohne nenenswerten Hardware Invest einige Tests gemacht:

SPS-Code in 1ms Timerinterrupt verlagern -> geht 20% load

Kommunikation Microcontoller zu PC per USB -> 1,6MByte/s, Bedarf 64KB/s

Einbindung Microcontoller an Raspberry -> geht ohne zusätzliche Treiber

HTML5 Website zur Bedienung-> nach 4 Wochen probieren , geht (Canvas und WebSocket)

Verbindung von Microcontoller , Datenaufbereitung und Verbindung zur Website per Websocket und JSON geschrieben in Python. Geht

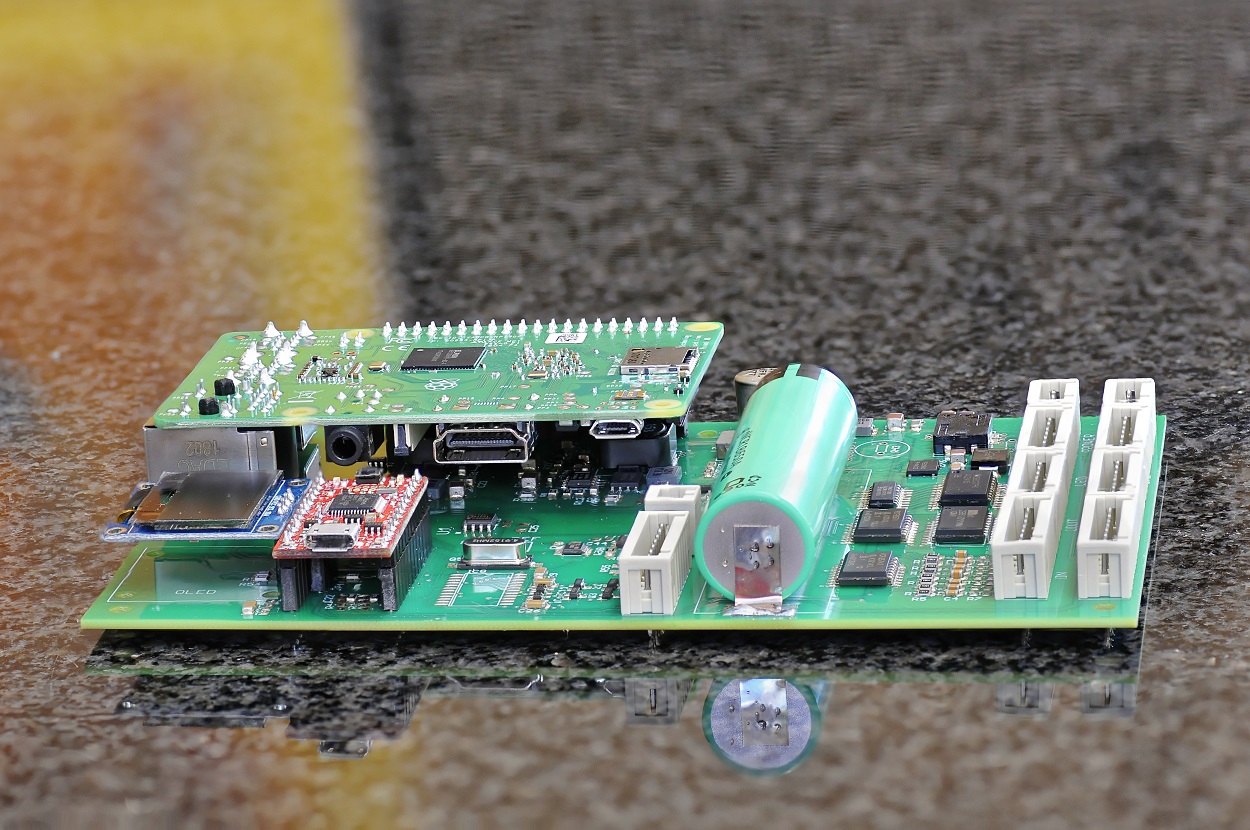

So nun alles auf ein Board und die eigendliche Enwicklung beginnt.

Tools: C auf dem Controller, Python auf dem Pi und HTML5 für die Seite.

Auf dem Board sind Netzteil, USV, OLED, AD7730, DA, Micocontoller, 24V IO, RFID.

Das Board ist auf Anfrage erhältlich.